7 Location Factors For Manufacturing

- 7 Location Factors For Manufacturing Process

- 7 Location Factors For Manufacturing Industry

- 7 Location Factors For Manufacturing Overhead

Factors of industrial location (Locational factors) The term industry covers a multitude of meanings; in its narrowest sense, it may only refer to manufacturing- the making of goods. This conjures up visions of factories and mills and it is in consequence rather limited in scope.

- An ideal location may not, by itself, guarantee success; but it certainly contributes to the smooth and efficient working of an organization. A bad location, on the other hand, is a severe handicap for any enterprise and it finally bankrupts it. Locational decisions generally arise when: A new manufacturing (or servicing) unit is to be set up.

- Raw Materials: ADVERTISEMENTS: The significance of raw materials in manufacturing industry is.

ADVERTISEMENTS:

7 General factors influencing location of industries in India are: 1. Raw Material 2. Energy 3. Transport 4. Labour 5. Water 6. Market 7. New Factors in a Changed Situation.

The decision regarding the location of a particular industrial activity is guided by many factors which may be geographical, socio-political, economic and historical.

ADVERTISEMENTS:

These factors, specific to the Indian conditions, are discussed below:

1. Raw Material:

The earliest industries in India developed near the sources of raw material. For instance, the textile mills of Bombay had supply of cotton coming from Gujarat and Vidarbha and the jute mills of Hooghly region got the raw material from the delta region of the Ganga. The nature of raw material also has a bearing on the location.

For instance, those raw materials which get reduced in weight during manufacturing (i.e., which are perishable) influence the industry to be located near the source. This explains the particular location of sugar mills in Maharashtra and western Uttar Pradesh and of iron and steel industry in West Bengal-Bihar- Orissa belt.

2. Energy:

The iron and steel industry has been traditionally tied with the coal resources, as it uses coking coal for fuel. Similarly, the electro- metallurgical and electro-chemical industries, being power intensive, have been located where electricity is easily available.

This explains the location of aluminum producing units at Korba and Renukoot in Madhya Pradesh and of the fertiliser plant at Nangal in Punjab. However, since electricity can be easily transmitted, and petroleum can be transported, these industries can also be dispersed. It was only because of the transmissibility of electricity that industrial development could take place with hydel power in the coal deficient peninsular region.

ADVERTISEMENTS:

3. Transport:

Transport is required for carrying raw materials to manufacturing units and finished products to the market. The earliest industries developed near the port towns of Kolkata, Mumbai and Chennai, since these ports were linked with rail and road to hinterland. This infrastructure for transport was further developed after independence.

4. Labour:

The availability of both unskilled and skilled, or technically qualified manpower, is an important factor in the location of industries.

Unskilled labour is easily available in urban locations due to large rural-urban migration. One characteristic feature of the labour factor is its mobility. The industrial belt around Mumbai attracts labour from all over the country. Some of the small scale industries traditionally associated with labour is glasswork (Ferozabad), brass-work (.Moradabad), utensils (Yamunanagar in Haryana), silk sarees (Varanasi), carpets (Mirzapur), etc.

ADVERTISEMENTS:

Water is required to produce hydel power and in the process of manufacturing for cleaning, cooling, washing, etc. The industries which heavily depend on water, for one purpose or the other, include iron and steel (for cooling), textile (for bleaching and washing), paper and pulp, chemical, jute, food processing, leather and atomic power. Naturally, these units are located at places where water is easily available.

6. Market:

High demand and a satisfactory purchasing power give impetus to industrial development. Government policies facilitate expansion of the market and, thus, of the industry. Market may be local, national or international.

7. New Factors in a Changed Situation:

With scientific and technological advancement, the constraining geographical factors have not remained rigid. Labour has become more mobile, long distance transmission of energy is possible now and alternatives of various raw materials are available. Therefore, new factors have come into play which include skilled managerial services, availability of capital and financial resources and export potential of products.

The government policies seek to promote regional parity by locating the industry in backward regions. For instance, such objectives guided the government’s decision to locate an oil refinery in Mathura, a coach factory in Kapurthala, and a fertiliser plant in Jagdishpur, Uttar Pradesh.

7 Location Factors For Manufacturing Process

Government policies also seek to check environmental degradation and to reduce congestion. Export potential of iron and steel products guided the location of new steel plants at Visakhapatnam and Salem. Visakhapatnam is a port, while Salem is well connected to the ports of Chennai and Kochi by rail and road.

The term industry covers a multitude of meanings; in its narrowest sense, it may only refer to manufacturing- the making of goods. This conjures up visions of factories and mills and it is in consequence rather limited in scope. In its broadest sense, it is refers to all stages and types of economic activity including extraction, construction and services. This later definition is the more common in economic geography. It is therefore quite acceptable to speak not only of, say, the steel industry or textile industry, but also of the tourist industry and even the music industry.

However, the most usual classification of industry is in four-fold and it is based on the nature of the work undertaken and the stages in the production process.

What is Industry?

An industry is an economic activity which is concerned with the production of goods, extraction of minerals and provision of services

Different Types of Industry

- Primary industry-primary industry is any activity in which natural resources are acquire from the earth surface. Examples of primary industry include agriculture, fishing, dairy farming, forestry, mining, and quarrying. In other words, such industry is located where naturally occurring commodities are collected, but they do not physically changed into final good in any way.

- Secondary industry-secondary industry deals with the manufacture of finished products; this is where the resources that were collected at the primary level are changed into other products, thereby involving a certain amount of manufacturing. The goods are made either for other manufacturers or for the general public, in either case, the raw materials undergo physical change. Examples of secondary industry include making sugar from sugarcane, converting of iron ore to steel

- Tertiary industry-Tertiary industry may be summarized as the distributive trades and as such, it includes the commercial services such as transport, wholesaling and retailing. It deals only with goods and forms a link between the first two industries and the customers.

- Service industry/Quaternary industry- quaternary industry comprises of all personal services. Unlike tertiary industry, it doesnt deal with goods but with people and requires generally higher levels of skill, expertise and specialization. Activities in such fields such as education, research, administration and financial management may be termed quaternary.

Most of the goods we buy have passed through or have been affected by all the four types of industries. For instance, the motor car we purchase, mining for iron ore and coal, quarrying for sand and collecting of tree rubber are all examples of primary activities. The transformation of these raw materials into steel, glass, tires and the subsequent manufacture of the car itself may all be grouped into secondary activities. However, the removal of the car to the showroom and its sale to the consumer are part of tertiary industry. Quaternary activities are necessary for all these processes to take place since they include the management of the individual firm, the supply of finance and the design of the final products. These are all termed quaternary activities. The consumer requires quaternary services in the firm of motor assurance and possibly a bank loan with which to purchase the car.

Industrial Location

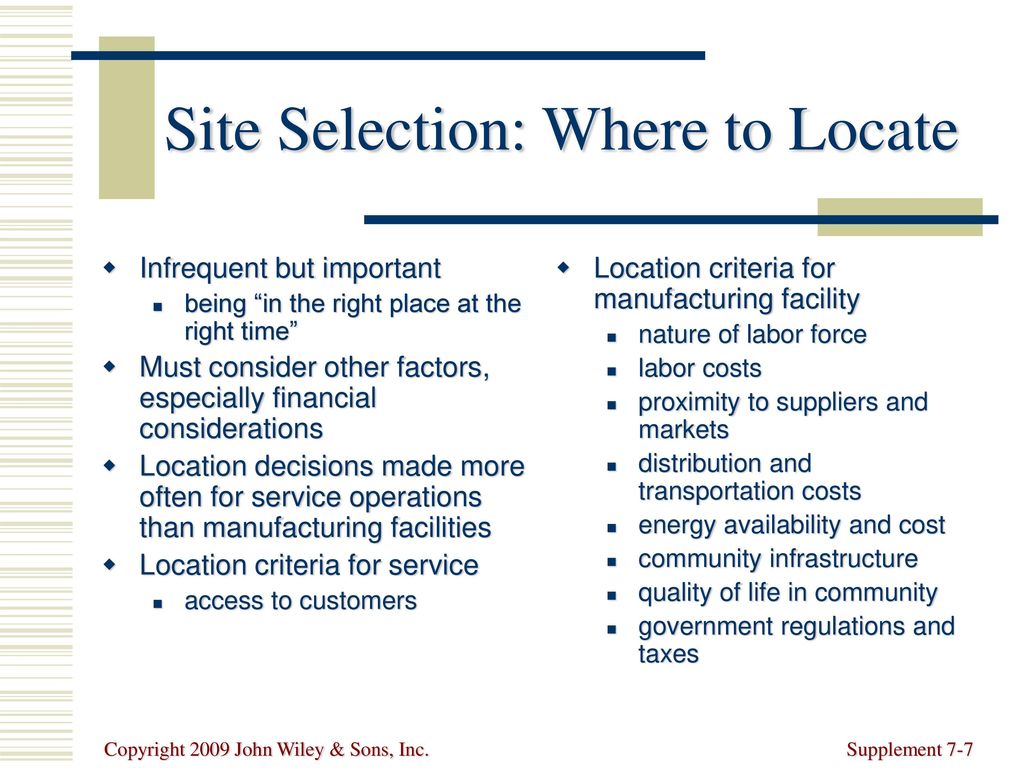

There are two types of approaches to industrial location; one is regional and attempts to assess the reasons why certain locations are attractive to industrialization generally. This may be viewed on any scale from local (within a town a country) to international (between countries, continents and latitudes). The second approach is industrial in perspective and seeks to explain why an individual industry or firms are attracted to a particular location. This involves the study of a particular need of different industry, why those of one industry may differ from those of another. In this case, these two approaches complement one another.

The factors to be considered are many; they include aspects of physical geography, economics, human, social considerations and politics. However, to generalize about the relative importance of each these factors is dangerous; this is partly because they are not in isolation but in complex inter-relationships and partly because their significance may change over time between areas and from industry to industry. Even so, it is probably true to say that whilst, environmental factors determine the overall regional pattern of industrialization, economic factors are more likely to direct industries to particular sites.

In deciding upon a final location, the industrialist must weigh up the relative merits of all potential locations and then select that which best suits the particular need of the firm. This doesn’t mean that he will choose the location with most advantages. Usually, areas possess advantages and disadvantages and manufacturing plant is likely to be located where the favorable factors outweigh the unfavorable factors.However, it should also be noted that the best location for one firm might not be the best for another and that the advantages as perceived by one industry may be viewed as disadvantages by another, these perception vary from individual to individual.

7 Location Factors For Manufacturing Industry

If an industry has a particulareconomic bias, it is dependent: Primary industries should be located where there are natural resources and the tertiary and quaternary industries, which are market oriented, should be found inurban areas. However, what will now be the case of secondary industries which are not oriented toward any one economic factor? The optimum location may be near raw material or near labour supply, or even near markets. Some industries like light engineering seem not to be tied to any special kind of location and are called footloose. Even those ones that appear to have similar economic structures and requirements are frequently found in different types of locations.

Pottery making is an example of secondary industry

Factors of industrial location (Locational factors)

7 Location Factors For Manufacturing Overhead

- Physical geography– the importance of relief and climate is often overlooked in the study of industrial location. This is unfortunate since these physical factors exert an overriding influence on the pattern of industrialization. People tend to work only where living conditions are favourable. Any atlas will show that industrial regions are usually associated with areas of low relief and moderate climate even within small areas.

- Land: although strictly physical lands may be considered separately. In the economic sense, it contains wealth in the form of raw materials and potential power supplies. Generally, industries that lose either bulk or weight in the manufacturing process or which use highly perishable primary products tend to be located near their raw material because it is undesirable to transport either waste or materials which may become unusable, the former for the reason of cost , the later for reason of efficiency and standards of production. For instance, copper smelting, iron, steel industry, cement making and most types of food processing fall into this category. It should be mentioned at this point that the importance of both raw materials and power supplies is now declining; this is due to improved transport and technology.

- Water– water supply may also be considered under the heading of land as would be expected. Industries which use large quantities of water either for cooling purpose (for instance steel making and power generation) or for processing (for example, brewing) will be found at rivers or wells if fresh water is needed or at the coast if salt water is need. In Britain, brewing takes place along the river trend and most nuclear power stations (Dungeness, Bradwell and Oldbury) are sited on the coast. There are some basic land requirements commanded by all firms such as sufficient space and flat surface both of which reduce cost of building. In addition, some firms require land where waste disposal is both easy and cheap.

- Capital -this includes fixed capital, (building and machinery) and financial capital- money, both may be of importance to the location of industry. The cost of building erected acquiring fixed capital varies prom place to place and areas where costs are low will have a greater pull than those where they are high. This is particularly significant in the location of small or new firms, which often find existing buildings attractive propositions since converting, and using them will save time and money. For this reason, building erected for one purpose might now be used for another purpose. Cotton mills, wartime ammunition factories and even old railway stations or post office are common examples of this. Such places are now used commonly for small-scale electrical engineering and specialist textile manufacture. The availability and cost of investment capital exerts no less pull and this could explain why centres of finance such as the city of London and New York have also become industrial centres.

- Labour– the cost and availability of labour together with its quality vary spatially. Areas with skilled or versatile labour will tend to be attractive to automated or specialist firm, while areas where there are vast quantities of unskilled or possibly cheap labour will attract large scale of labour- intensive firms. Other considerations to be taken into account include stability and efficiency of labour, absenteeism and labour relations, in the past, there have been suggestions that the Ford Motor Company might leave Britain, such is the country poor record of strikes. It must be borne in mind that the importance of labour factor is governed to a certain extent by its mobility. Labour can be either geographically or occupationally mobile: that is it can move between places and regions or between jobs. Generally, the less mobile it is, the greater will be the significance of labour as a locational consideration.

- Management– this was once considered as part of labour, but now management and entrepreneurial enterprise is now more often discussed separately. The success of any industry is dependent upon the ability of its management. Yet such skills are not evenly distributed. In Britain for instance, South-East England is believed to possess a larger number of high calibre of executives that other regions do not have and therefore, it has a corresponding stronger industrial pull.

- Transport– transport facilities are essential to all firms, therefore, areas well provided with sufficient transport routes will attract more industries than those where such facilities are lacking. This is why firms are situated along roads and canals and around harbours and railway stations. It should be pointed out that firms aim to reduce economic distance rather than actual distance. In other word, they aim to reduce transport costs.

- Markets– as we have seen, a firms market could be the general public or another firm. In both cases, its importance as a locational factor is growing, even for firms not formally considered to be market oriented. This is because technological advances and improved transport have reduced the importance of other locational factors. For instance, coal can be transported much more cheaply than formerly. However, in developed countries, there has been an increase in luxury consumer goods which by their very nature are market oriented. Markets are usually found in towns where labour and capital are available, thereby, the market appears more important than it really is as a locational factor.

- Human and chance factors– occasionally, industries and firms have been located and have grown in areas for no apparent physical or economic reason. These may be considered as chance locations. Sometimes, firms have started up by accident, sometimes because a manager or owner has chosen a site which he personally like. One of the most famous examples of such a location is the motor vehicle industry in Oxford. This began when William Morris, a repairer of bicycles bought the old school where his father had been educated and converted it into his first factory.

- Politics– it is assumed that industries are free to develop anywhere depending on a combination of physical and personal factors. Yet, in reality, this is not always true. Often, industrial location is the result of government intervention for various social, political and strategic reasons most countries today have policies that persuade or force industries to locate in a particular area where they are presently. For instance, USSR industries have been moved eastward into the Urals, Tashkent and Ukraine. For the same defensive strategic reasons, the USA has located its aircraft industry away from the eastern seaboard. Even on a small scale, local authorities may influence the location of industries. Land use-zoning policies for instance, can prevent firms from moving into residential areas or regions of beautiful countryside.

- Industrial agglomeration– industrial concentration occurs when an area offers the greatest relative advantage to a variety of firms. Different firms share the same locational requirements. In each of these, agglomeration may be found in all types of industries located side by side. These and the firms that make them up may have strong functional linkages which bind them together and will probably achieve financial savings or external economics of scale by sharing transport facilities, research, administration, social services and so forth. Agglomerations can bring to the firms not only benefits, but also drawbacks. Frequently, heavy concentrations can lead to overcrowding, congestion, higher land prices and pollution. There may even come a time when firms will actually benefit by moving away from an agglomeration- a process that is often called deglomeration. Such movement is now becoming apparent in Greater London and is being encouraged by the government regional policy.

- Industrial inertia: industries may remain in a particular location long after the reasons for being there have disappeared; this occurs as a result of two main factors. The first factor is that physical capital is fixed once the land has been acquired, factory built and machinery installed, there is a great incentive for a firm to stay where it is because the enormous cost of relocation would indeed outweigh any financial savings made at a new site. The second reason is that once located, a firm acquires secondary advantages. This benefits of agglomerations already mentioned would exert a magnetism from which a firm may find it both difficult and expensive to break away